Syclone ATTCO Service specializes in creating solution based ergonomic lifting devices to fit almost any lightweight lifting application. The Sky Hook is a small crane style hoist lift designed as a portable, safe, high quality lifting solution. Standard models offer a wide range of base options to accommodate a variety of needs; however for or lifting applications requiring alternative dimensions or features, the sales and design teams at Syclone ATTCO Service can modify the Sky Hook industrial lifting device to best fit the application.That's where customization comes into play!

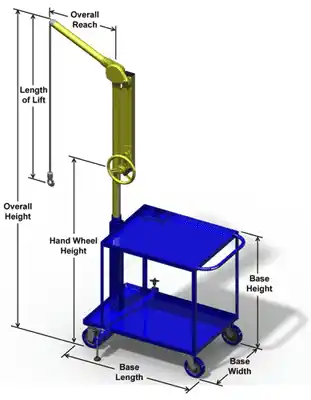

The Sky Hook lifting device is ideal for all types of industries from manufacturing and material handling to maintenance and safety. Taking into consideration the hook reach and height requirements of your specific lifting application, the Sky Hook can be completely custom built to the key dimensions you need. Custom modifications involving increased or decreased height and reach, along with moving the hand wheel location or orientation, are available.

In addition, the Sky Hook can be modified to best suit specialized environmental requirements, such as cleanroom, anti-static, or outdoor applications.

Syclone ATTCO Service has been creating unique, customer driven Sky Hook creations for the past 50 years. As such, we have streamlined the capabilities for generating quick, visual representations accompanied by quotes with accurate and reasonable pricing for custom requests. We have also greatly improved the production process to accommodate the vastly growing needs of the industrial consumer.

While the standard customizations allow the user to utilize a variety of customization options to fit their required needs, there is always the possibility of needing a customization that is unique to that particular application. One that will create a solution which no off-the-shelf portable hoist or portable gantry crane in the world can offer. That's why the design team at Syclone ATTCO Service. is ready at a moments notice to help you create your unique lifting device. Armed with 3D Solidworks CAD design capabilities, an entire firm of certified engineers, and a fully operational fabrication shop, Syclone ATTCO Service. can make any idea or impossible creation a reality. Give us a call today to begin the design process.